Hollow Plate Production Machine V shaped Pp Hollow Plate Production Machine

Product Details:

- Type Hollow Plate Production Machine

- Click to View more

Hollow Plate Production Machine V shaped Pp Hollow Plate Production Machine Price And Quantity

- 1 Set

Hollow Plate Production Machine V shaped Pp Hollow Plate Production Machine Product Specifications

- Hollow Plate Production Machine

Hollow Plate Production Machine V shaped Pp Hollow Plate Production Machine Trade Information

- 10000.00

- 100 Set Per Year

- 45 Days

- wooden case and wrapping film,etc sea worthy package

- All India

Product Description

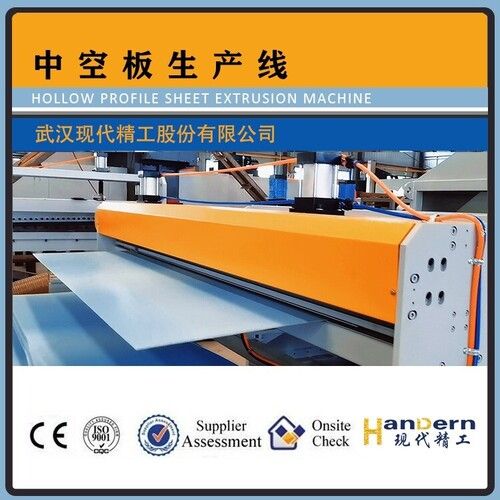

Hollow Plate Production Machine V-shaped Pp Hollow Plate Production Machine

At the same time, the plastic hollow board and its products can be recycled, cleaned and reused. As a new green material, it is an ideal substitute material for cardboard, board and aluminum board in many fields

Plastic hollow board is a new type of green product with green requirements.The product has a large internal quality, flat surface, breaking strength, flame retardant, surface water and steam through the amount of 0, heat insulation, good energy saving function.The condenser refrigerator has excellent heat insulation effect.The company can make various specifications of refrigerators, freezers, washing machine back and bottom plate according to customer requirements

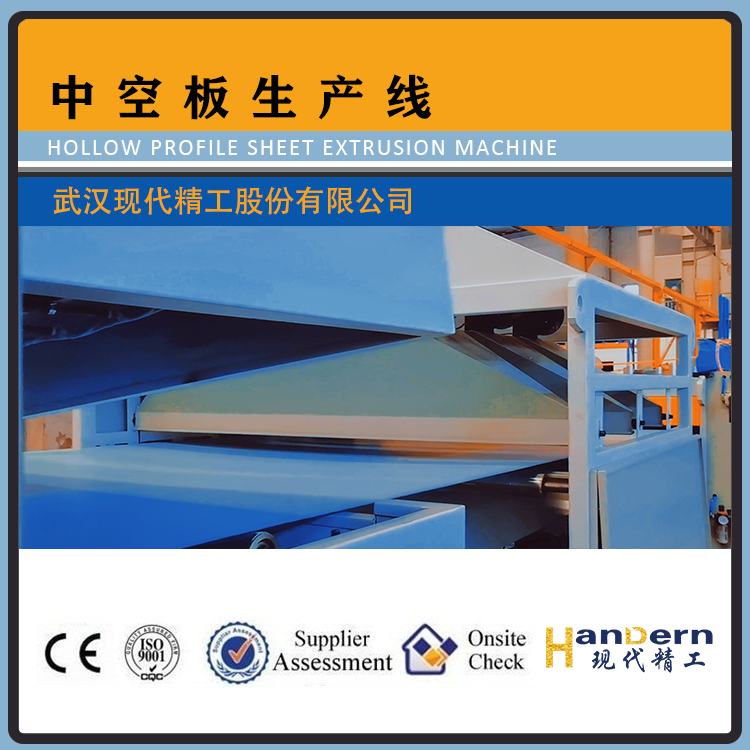

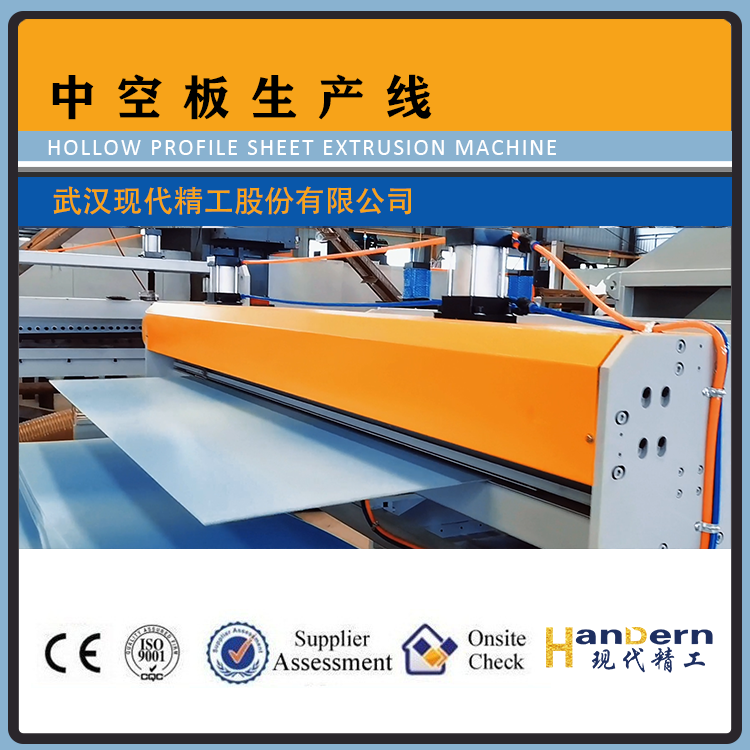

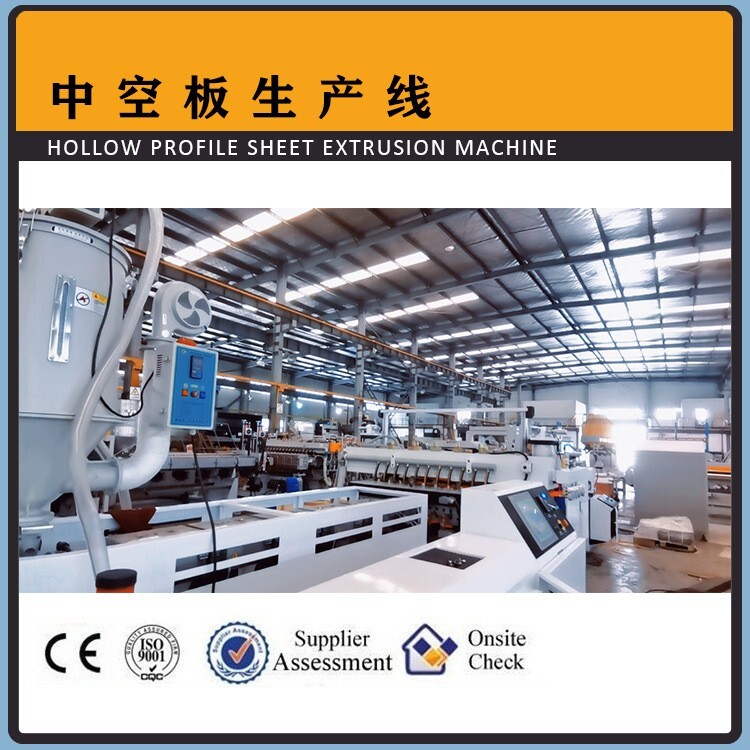

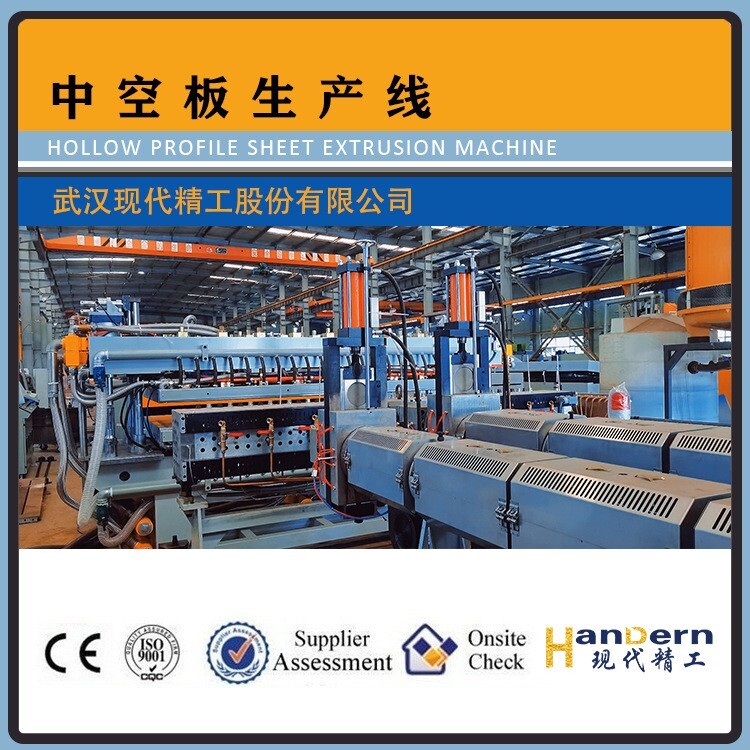

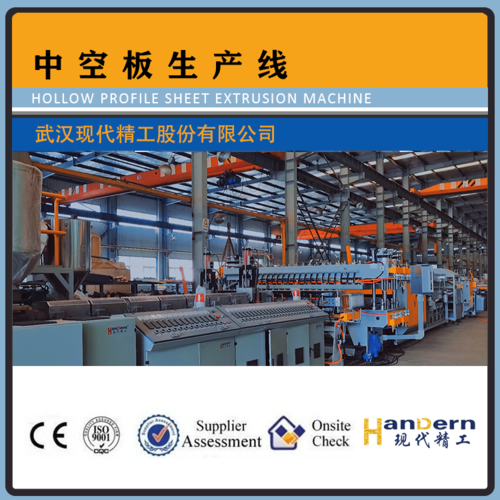

Our company produces a complete set of hollow plate production line from the feeding, extruder, mold, setting machine, traction and cutting key components are designed and manufactured by our company, to ensure the stability of mechanical product quality.

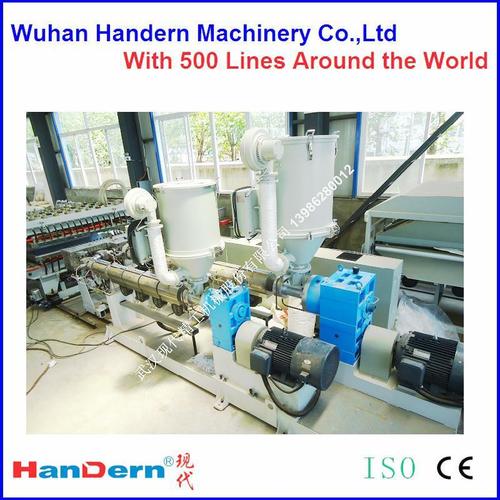

Extruder: special design of screw, special temperature control system, to ensure stable plasticizing performance and extrusion efficiency, the outstanding advantage of the company is high energy saving efficiency, the same output, motor power saving 20%

Mold: excellent alloy die lip and adjustable block to provide even pressure

Vacuum Calibrator: Array interleavement of the thermal convection system, ensuring calibration, and calibration of the vacuum system, which consists of two separate subsystems, equipped with a large number of closed loop vacuum lines.

Electrical control system: microprocessor unit PLC is used to control the parameters and optimize the operating characteristics

Wuhan Modern Seiko's hollow plate production solution includes the following main advantages:

1. PP hollow plastic building template has high strength, impact resistance, wear resistance, long life, and can be used for up to 30 times

2. PP hollow plastic building template machinability is good, can be seen, planed, nail, and wood template used at the same time

3. PP hollow plastic building template two surfaces (smooth or decorative surface) have different use effects.Such as the use of smooth surface in the concrete pouring after the demolition of the template, the surface of the ramming body smooth and clean, to meet the requirements of the surface and decorative water, no secondary plastering, material and time saving, reduce the cost of cleaning and maintenance, and the concrete formed after stable quality to save time.Suitable for basement engineering, highway and railway bridge piers and other wet environment;If use decorative pattern surface to be combined with plastering layer.The use of decorative surface on bridge piers not only meets the requirements of decorative surface and decorative water, but also plays a protective role because the decorative surface has the effect of light diffuse reflection and no strong light reflection affects the driver's line of sight.

4. The new hollow plastic building template has the advantages of light weight, convenient support and disassembly, low labor intensity of handling operation, high construction efficiency, no moisture absorption, corrosion resistance, acid and alkali resistance, smooth and clean surface and no need to brush demoulding agent.

5. The new type of hollow plastic building formwork can recycle waste plates and scraps by recycling, which saves cost and reduces pollution

6. The comprehensive use cost of the new hollow plastic building formwork can save more than 30% compared with the traditional wood formwork.

100#Hollow plate production machine V-shaped pp Hollow plate production machine

200#Hollow plate production machine V-shaped pp Hollow plate production machine

300#Hollow plate production machine V-shaped pp Hollow plate production machine

400#Hollow plate production machine V-shaped pp Hollow plate production machine

500#Hollow plate production machine V-shaped pp Hollow plate production machine

600#Hollow plate production machine V-shaped pp Hollow plate production machine