Sheet Making Machine Plate Corrugated Plastic Multi layer Pp For Producing

Product Details:

- Type Sheet Making Machine Plate

- Material pp pc pe

- Capacity 180~600 Kg/hr

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Dimension (L*W*H) 22*2*2.2 Meter (m)

- Click to View more

Sheet Making Machine Plate Corrugated Plastic Multi layer Pp For Producing Price And Quantity

- 1 Set

Sheet Making Machine Plate Corrugated Plastic Multi layer Pp For Producing Product Specifications

- PLC Control

- 22*2*2.2 Meter (m)

- 180~600 Kg/hr

- customized

- pp pc pe

- Automatic

- CE ISO

- Yes

- Sheet Making Machine Plate

Sheet Making Machine Plate Corrugated Plastic Multi layer Pp For Producing Trade Information

- 10000.00

- 100 Set Per Year

- 45 Days

- wooden cases and plastic film

- All India

- CE ISO

Product Description

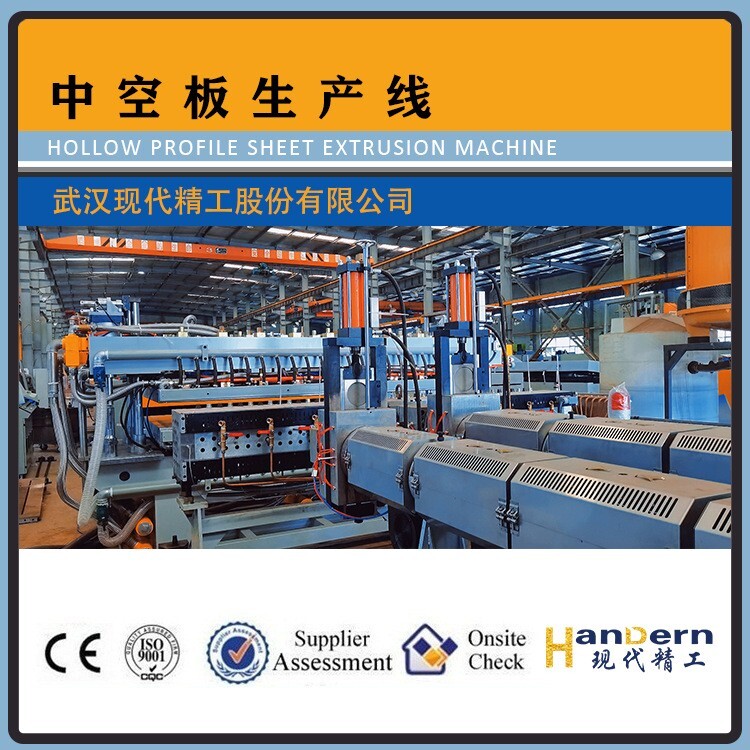

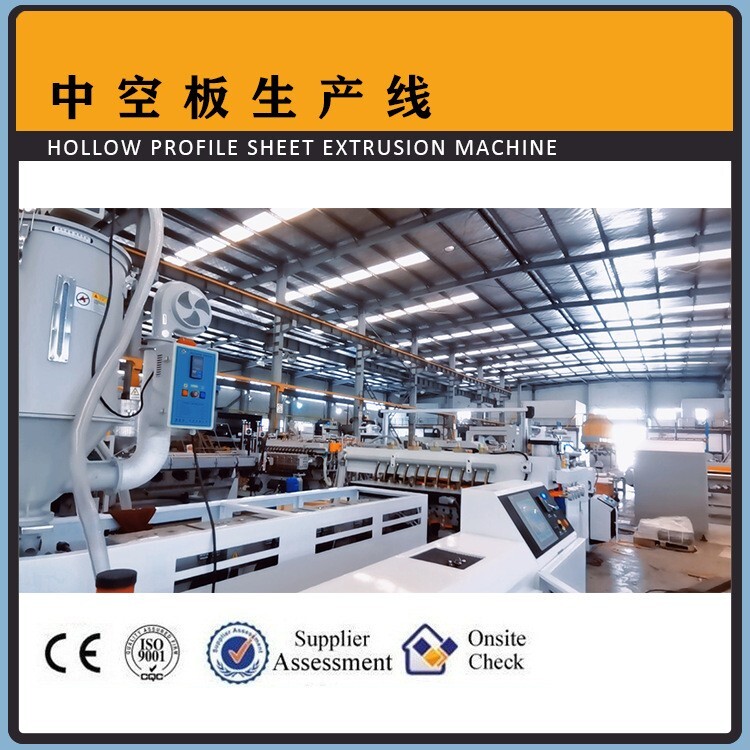

Sheet Making Machine Plate Corrugated Plastic Multi-layer Pp For Producing

PP/PE/PC hollow profile sheet extrusion machine data

Machine Type Sheet width(mm) Sheet thickness(mm) Max.Extrusion capacity(KG/H)

1400 1250 2-6 6-12 12-18 280/280/350

1800 1650 2-6 6-12 320/350/420

2300 2150 2-6 6-12 350/350

2400 2200 2-6 6-12 450

2600 2450 2-6 6-12 480

2800 2600 2-66-12 500

Hollow profile sheet main Applications:

Industrial packaging electronic circulating box, auto part circulating box, logistics circulating box etc

delivery packaging PP turnover container box, PP corrugated packaging box, PP turnover packaging box,Plastic fire-retarding packaging box for food, electrionic or delivery industry.

Advertisement displayed card,billboard,light box etc.

Home temporary partition,wall backplate,ceiling board etc.

Other applications backplate of washing machine,cars,and water heater,baseplate for delivery etc.

Advantages of hollow profile sheet:

1. Good mechanic property The special structure from plastic hollow board provides good reflexibility, anti-shock, high anti-pressure strength, higher hardness, good bent feature and shock buffer.

2. Light weight and material reduction Under the same effect, it can make plastic hollow board with material consumption reduction, costing lower and light weight.

3. Heat perservation and sound proof Hollow board hollow structure make it's heat and sound transfering effect abviously lower than solid board, reaching good heat perservation and soundproof effect.

4. Anti-static, electricity conduction and fire resistant Adopting changed property, mixed, surface spread, etc, makes plastic hollow board with the property of anti-static electricity,electricity conduction and fire resistant.

5. Stable chemical property Plastic hollow board can be water proof, damp proof, anti-erosion, compared with board free of fumigation, it has obvious advantage.

6. Smoothy surface, good looking apperance and complete color variety With special forming manufacturing process and adjusting color-master material, it can reach random color, and the surface is smoothy, printing is easy.

7. Good enviroment-protection effect Plastic hollow board has the features of non-toxic, free of polution, easy to handle, so it avoids polution, also can be re-used or being done to other plastic finished product.

Benefits of Polycarbonate hollow sheet making machine

1. Required high production efficiency

2. Production flexibility( controllable sheet thickness and width, for example, you can produce 2-6mm thick sheet with the same mould or machine)

3. Reliability and stability

4.Excellent Adaptability to different raw material and reach over 30% production cost reduction.

5. Size and shape diversity of finished products

Wuhan Handern Machinery Co.,Ltd.

Contact number: Whatsapp/Wechat +86-13986280012

Website: handern.en.alibaba.com

Handern.1688.com

Add:No.61 Yinbo Road,Jinghe Street,Dongxihu,Wuhan,Hubei,China

1000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing

2000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing

3000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing

4000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing

5000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing

6000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing

7000#Sheet Making Machine Plate Corrugated Plastic Multi-layer PP for Producing