Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

Product Details:

- Product Type Other

- Technology Other

- Power Source Pneumatic

- Operating Type Automatic

- Power 1000 Horsepower (HP)

- Pressure 100 Pa

- Dimension (L*W*H) 25*3*2 Meter (m)

- Click to View more

Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine Price And Quantity

- 1 Set

Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine Product Specifications

- CE ISO

- 350 Ton/day

- Other

- Pneumatic

- 20 Short Ton

- Heating plate

- Other

- Automatic

- 1000 Horsepower (HP)

- 25*3*2 Meter (m)

- 100 Pa

- grey

Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine Trade Information

- 100 Set Per Year

- 45 Days

- Contact us for information regarding our sample policy

- WOODEN CASE AND PLASTIC FILM

- All India

- CE ISO

Product Description

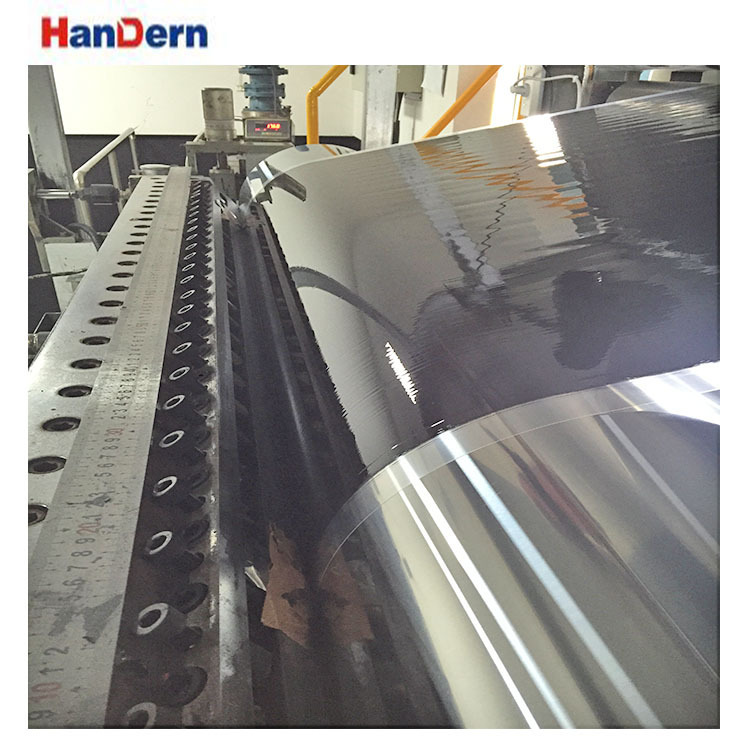

Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1. Project requirements:

2. Equipment structure: Combining graphene coating line with LDPE coating line, cutting machine, etc. to achieve the purpose of rational use of resources, energy saving, high automation and high production efficiency.

3. Equipment composition: PET double station unwinding, corona treatment, traction, slit extrusion die coating, drying tunnel, online inspection unit, copper strip conductive adhesive coating, copper strip unwinding, laminating compound, ultrasonic edge banding device, trimming, cutting, conveying, transmission system, tension control system and other units.

4. Number of coating layers: the first layer of graphene slurry, the second layer of copper tape conductive adhesive, and the third layer of LDPE coating.

5. Main Features:

1. The unwinding adopts double-station non-stop automatic roll change , high production efficiency, and can meet the requirements of different coating surfaces;

2. The slit extrusion die has high coating accuracy, and the coating error is less than 0.5 wire. The coating head and the dry glue inspection are in the same system;

3. The oven adopts a large arc design, and are sealed without gap between each two. Among sections 1-12 adopt top air supply. The hot exhaust gas is circulated into the air duct after being supplemented with fresh air, which greatly saves energy and reduces exhaust gas emissions. The temperature control of the oven adopts a digital temperature control system and uses SCR for adjustable power control, which reduces the impact on the grid due to high-power electric heating.According to production process requirements, it can be adjusted to low power operation, thereby greatly reducing energy consumption;

4. Squeegee adjustment mechanism for copper tape conductive adhesive. The squeegee can be quickly adjusted up and down, front and rear, and the elevation angle, which improves the uniformity of the coating;

5.Laminated film compound is manufactured using the technology which was granted the Patent for Energy-saving Extrusion Technology of Chaos Mixing"and won the Science and Technology Progress Award.It has the characteristics of low energy consumption, excellent extrusion efficiency, good plasticization effect and high production capacity;

6.The precise tension section control system makes the substrate run more smoothly, reducing staff (the whole machine can be equipped with 3-4 people), and fully reflecting the

maximum efficiency.

Coating material width and line speed:

The designed maximum material width:1300mm

The maximum mechanical speed : 20m/min

1000#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1100#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1200#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1300#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1400#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1500#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine

1600#Sheet Extrusion Lamination Compound Machine 1400mm Graphene Superconducting Sheet Extrusion Lamination Compound Machine