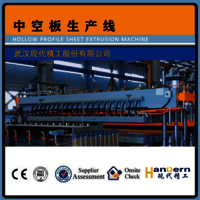

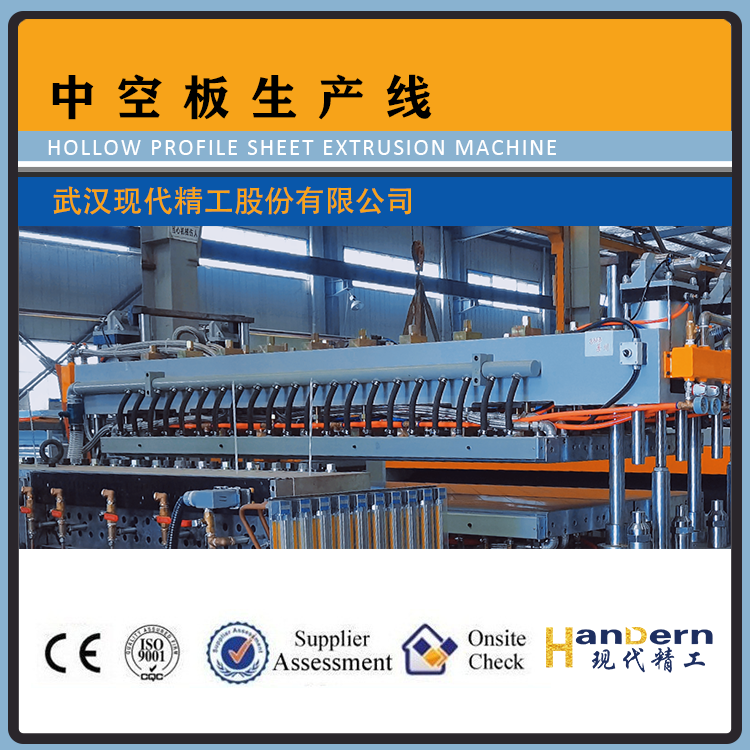

hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

Product Details:

- Type sheet making equipment

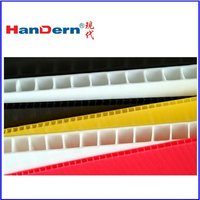

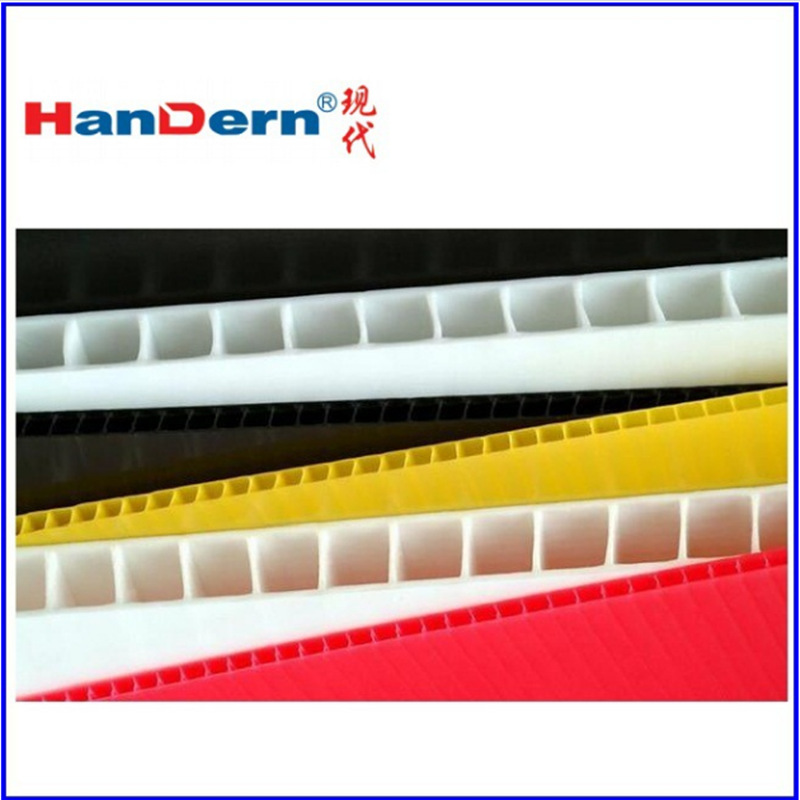

- Material pp pc pe ps pet abs hips pmma

- Capacity 180~600 Kg/hr

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Dimension (L*W*H) 22*2*2.2 Meter (m)

- Click to View more

hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment Price And Quantity

- 1 Set

hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment Product Specifications

- Yes

- pp pc pe ps pet abs hips pmma

- PLC Control

- sheet making equipment

- Automatic

- 22*2*2.2 Meter (m)

- 180~600 Kg/hr

- customized

hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment Trade Information

- 100 Set Per Year

- 45 Days

- Contact us for information regarding our sample policy

- wooden cases and plastic film

- All India

- ce/c

Product Description

Polycarbonate hollow sheet making machine is to produce PC hollow sheet;

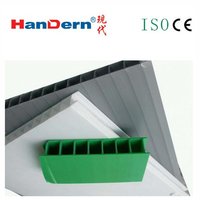

It can be used in many fields such as decoration,advertisement, sunshine and noise insulation, roofing, packaging.

Its performance is superior to that of calcium plastic corrugated board produced by traditional hot dip method, and it has good economic benefits.The unit has been exported to foreign countries and is well received by customers.

Ordinary production line, high speed production line, S type hollow board production line, rice type production line, multi-layer co-extrusion hollow board production line, V type hollow board.

Specifications of Polycarbonate hollow sheet making machine

Machine type1400180023002700

Max sheet width(mm)1250165021502550

Sheet thickness(mm)2-6 6-12 15-202-6 6-12 15-202-6 6-122-6 6-12

Line Speed(m/min)1-6 2-101-6 2-101-6 2-101-6 2-10

Max output(kg/h)180-260220-350320-450360-500

Motor power(kw)55-9075-11090-132110-160

Screw ModelSJ105/36SJ110/36SJ120/36SJ135/36 SJ150/36

Advantages of Polycarbonate hollow sheet making machine

New design screw extruder: line with market demands and adapt to many kinds of raw materials, with the advantages of good plasticizing, uniform distribution and high output.

Hydraulic pressure screen exchange: short course of changing screen and stable operation of operators

Mlding die: with high quality alloy steel lips and restrict bars to ensure even pressure and uniform thickness of the finished sheet.

Vacuum Calibrator: convective heat with array interleaved to ensure high precise calibration. the vacuum system composes two independent subsystem, equipped with several closed loop vacuum lines, which carries vacuum regulating system and vacuum displaying system, to ensure stable and even vacuum degree of sheet surface.

Haul off Device:

First haul off device is of high power, high reduction gear ratio, multi roll type, high traction, to draw the sheet up from calibrator evenly and synchronizedly.

Second haul off device is to remove stress and equipped with edge cutting device to ensure effective width and smooth cutting.

Cutting Machine: Accurate imported automatic length indicator, adopts electric fly cutting and traversing cutting.

Electrical control system: adopt PLC to control precise parameters.

Benefits of Polycarbonate hollow sheet making machine

1. Required high production efficiency

2. Production flexibility( controllable sheet thickness and width, for example, you can produce 2-6mm thick sheet with the same mould or machine)

3. Reliability and stability

4.Excellent Adaptability to different raw material and reach over 30% production cost reduction.

5. Size and shape diversity of finished products

100#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

200#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

300#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

400#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

500#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

600#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

700#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment

800#hollow sheet making equipment PP plastic hollow sheet making equipment 1200mm hollow sheet making equipment