Extrusion Lamination Compound Machine Single Side Extrusion Lamination Compound Machine

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 1000 Watt (w)

- Surface Treatment Other

- Dimension (L*W*H) 25*3*2 Meter (m)

- Click to View more

Extrusion Lamination Compound Machine Single Side Extrusion Lamination Compound Machine Price And Quantity

- 1 Set

Extrusion Lamination Compound Machine Single Side Extrusion Lamination Compound Machine Product Specifications

- Automatic

- Other

- Other

- 1000 Watt (w)

- 25*3*2 Meter (m)

- 2 Long Ton

- CE ISO

- Electricity

- metal

- 350 Kg/hr

- Other

Extrusion Lamination Compound Machine Single Side Extrusion Lamination Compound Machine Trade Information

- china

- 100 Set Per Year

- 45 Days

- Contact us for information regarding our sample policy

- seaworthy packaging:wooden box and breathable film

- All India

- CE ISO

Product Description

Extrusion Lamination Compound Machine Single Side Extrusion Lamination Compound Machine

Product introduction:

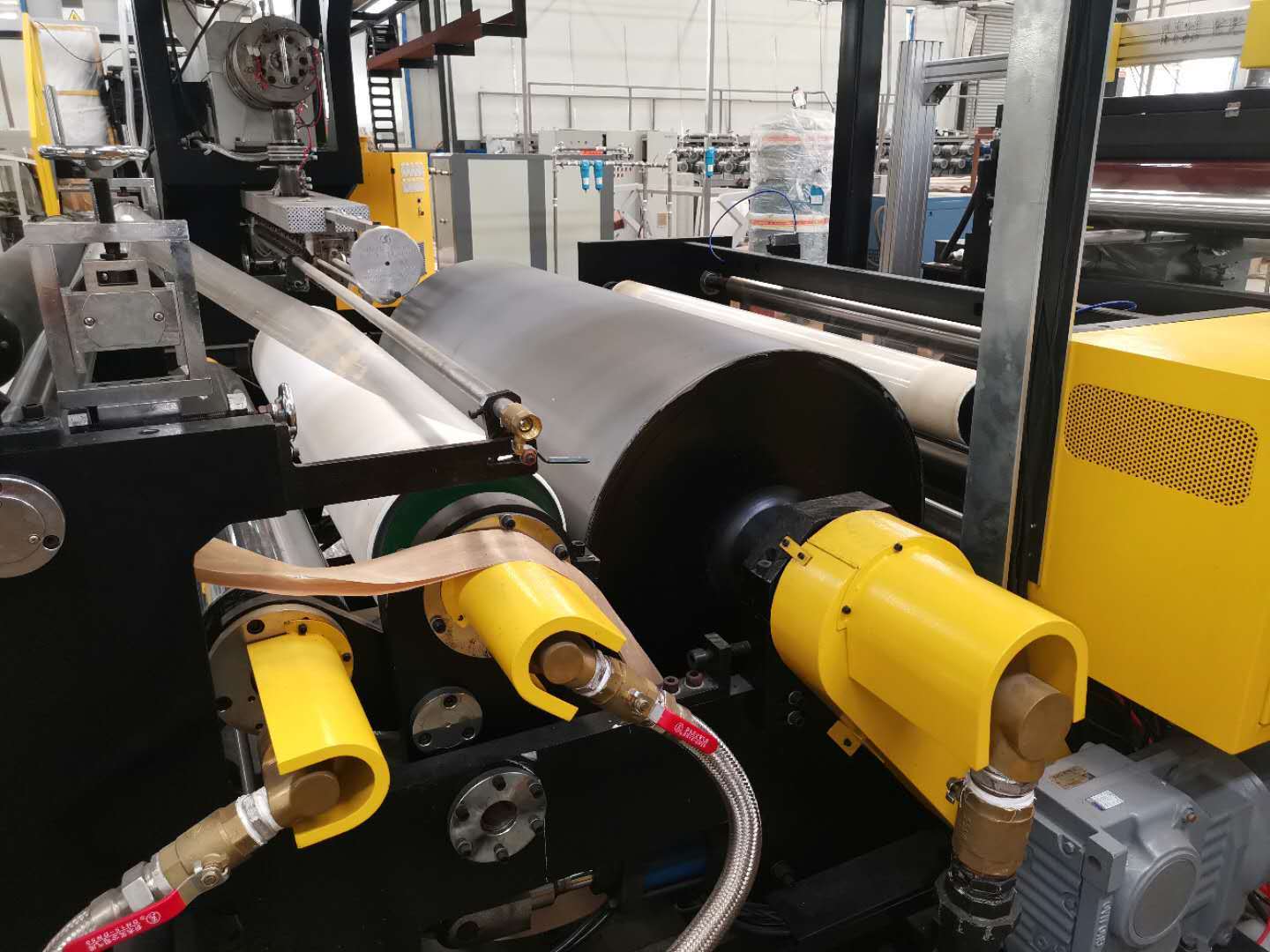

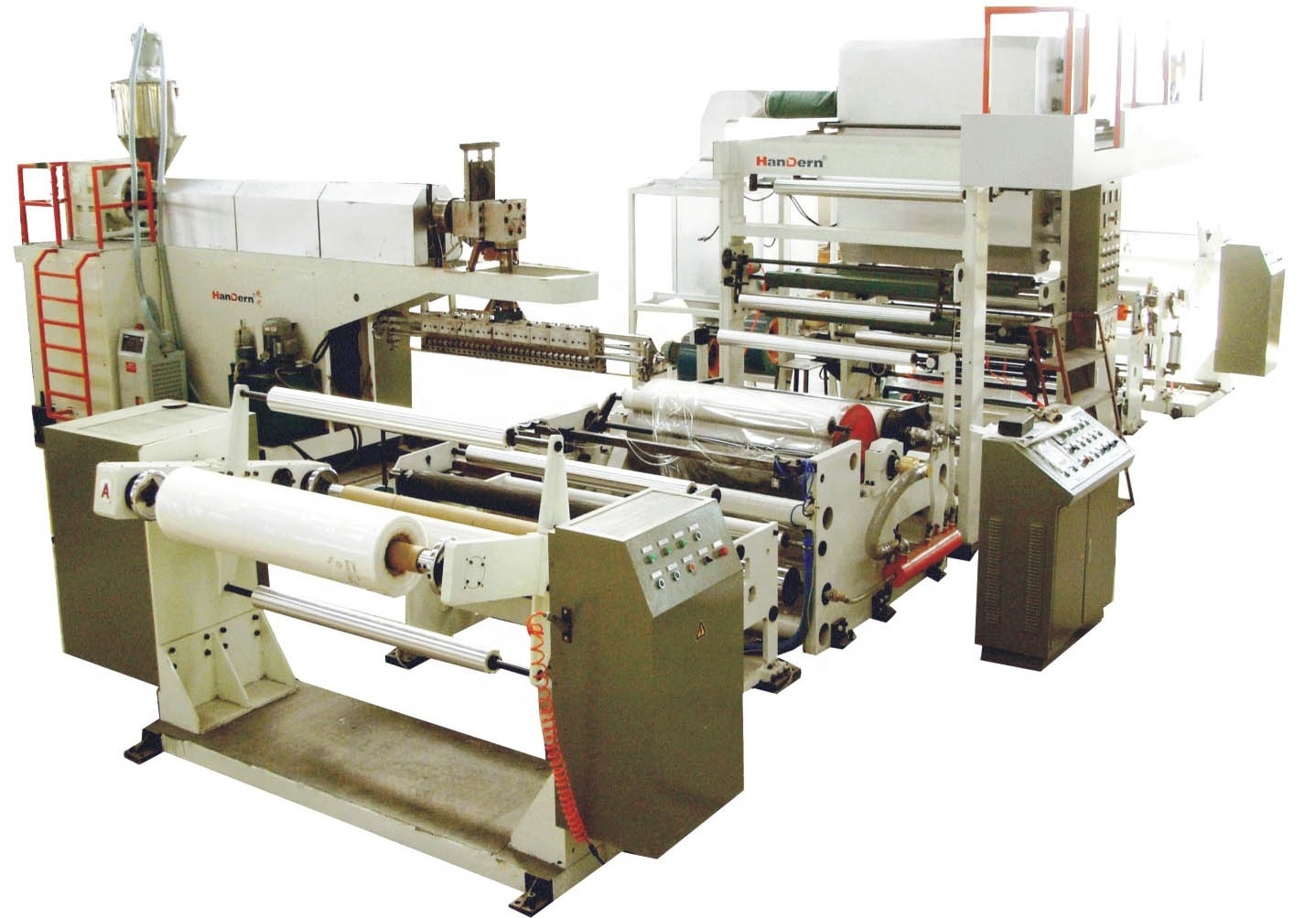

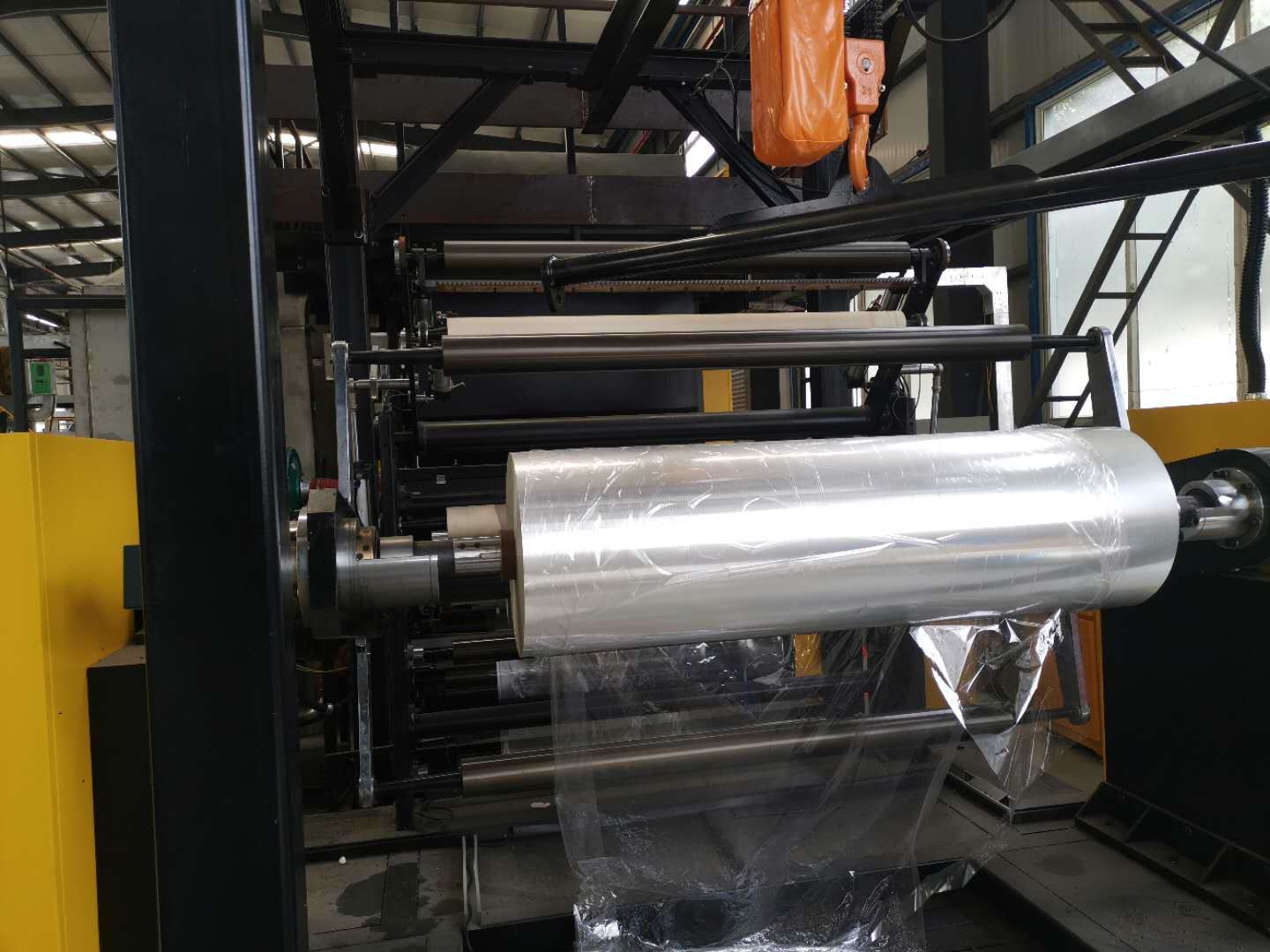

Features: the unit is composed of unwinding section, precoating section, extrusion casting section, composite forming section and winding section. It is fully computer controlled, highly efficient and of high quality.

Process principle: after plasticizing and extruding, the raw materials are coated on one or two sides of paper, aluminum foil, film and other substrates at high speed, as well as on packaging color printing substrates. It is an ideal equipment to improve the tensile strength, air tightness and moisture resistance of the substrate.

Product use:

Paper: kraft paper, dust-free paper, white cardboard composite, used for book packaging, melon seed packaging, garbage bag tape, etc

BOPP, BOPET, BOPA and other plastic film materials are compounded with PE and PP coating materials

Non woven fabric and PE, PP film composite

Composite of aluminum foil and PE film

Main technical parameters

Product width (mm) 800-3600

Maximum linear velocity M / min 80-150

100#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine

200#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine

300#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine

400#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine

500#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine

600#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine

700#Extrusion Lamination Compound Machine Single side Extrusion Lamination Compound Machine