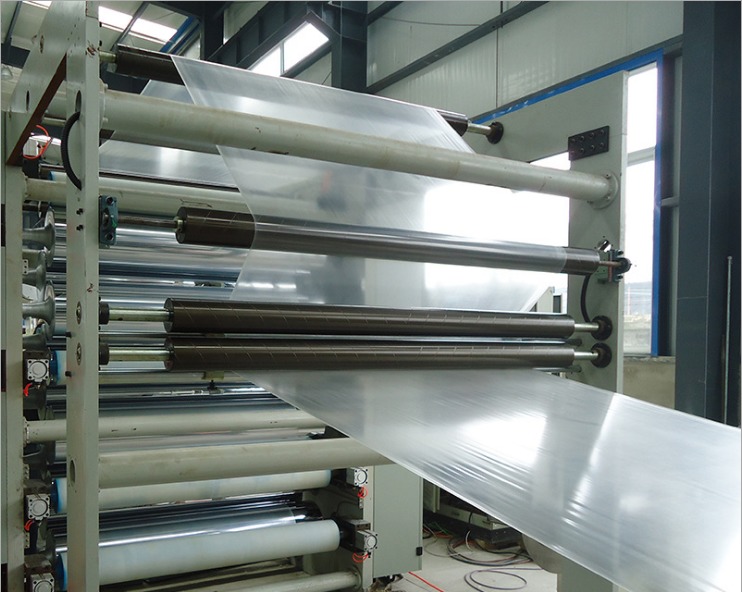

Extrusion casting protective film making machine PE Extrusion casting protective film making machine

Product Details:

- Product Type Plastic Processing

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 1000 Watt (w)

- Surface Treatment Coated

- Dimension (L*W*H) 25*3*2 Meter (m)

- Click to View more

Extrusion casting protective film making machine PE Extrusion casting protective film making machine Price And Quantity

- 1 Set

Extrusion casting protective film making machine PE Extrusion casting protective film making machine Product Specifications

- grey

- Electricity

- Coated

- 25*3*2 Meter (m)

- Plastic Processing

- Automatic

- 1000 Watt (w)

- CE ISO

- 350 Kg/hr

- Other

- 2 Long Ton

Extrusion casting protective film making machine PE Extrusion casting protective film making machine Trade Information

- wuhan

- 100 Set Per Year

- 45 Days

- Contact us for information regarding our sample policy

- seaworthy packaging:wooden case and breathable film

- All India

- ISO CE

Product Description

More than 5 years of experience in researching and manufacturing the breathable film extrusion line allows us to gain advanced extrusion technologies.

Introduction of Cast PE Breathable Film Machine

This machine can cast PE, PP, EVA, PEVA, TPU films which are widely used for hygiene, medical and packaging applications. Cast film machine have some advantages compared with blown film machine.

Applications of Cast PE Breathable Film Machine

Personal hygiene products: tampons, baby diapers, green scrubs, disposable bed sheet

Daily necessities: raincoat, gloves, waterproof clothing,raglan sleeve;

Building products: breathable materials, etc.

Specifications of Cast PE Breathable Film Machine

|

Width of die(mm) |

1600-3000 |

||

|

Width of breathable film(mm) |

1200mm-2600 |

||

|

Linear Speed(m/min) |

100-250 |

||

|

Width of finished film(mm) |

Weight of finished film(gsm) |

Maximum Production Capacity(kg/h) |

200-300-400-500-600 |

|

Installed power(kw) |

380 |

1

1.equipped with professional extrusion and recycling system for edge trim online

2.advanced vertical or horizontal stretching unit, convenient and safe to haul off the film;

stretching ratio can be adjusted according to products' requirement;

3.The whole line is controlled by touch screen and PLC, and all kinds of emergency buttons are complete and easy to operate;

4. latest winding tension control unir with stable, reliable, precise measurement.

5.optional online cutting unit and printing unit, it can realize automatic flow operation;

100#Extrusion casting protective film making machine PE Extrusion casting protective film making machine

300#Extrusion casting protective film making machine PE Extrusion casting protective film making machine

400#Extrusion casting protective film making machine PE Extrusion casting protective film making machine

500#Extrusion casting protective film making machine PE Extrusion casting protective film making machine

600#Extrusion casting protective film making machine PE Extrusion casting protective film making machine